Tank Cleaning | Upcoming guideline

Cleaning, productivity and sustainability

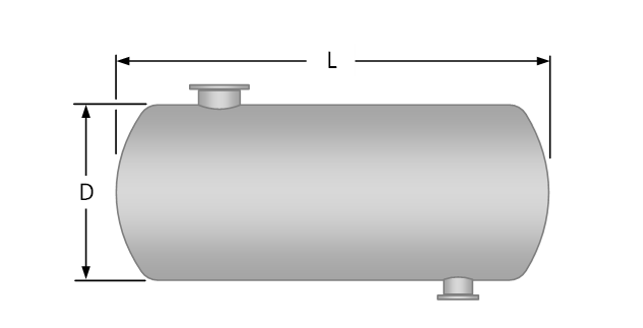

How to clean food processing tanks most effectively and efficiently? We first need to examine how our tanks are designed and constructed, because it’s the design of a tank that affects its cleaning potential, and consequently its effectiveness as a trustworthy part of a productive, safe and sustainable food processing line. The link between the hygienic design and cleaning aspects of tanks and vessels made the members of the EHEDG Working Group Tank Cleaning decide to include both the design and the cleaning aspects into one document.

Hygienic Design Guideline Cluster

EHEDG Guideline Document 51 is part of a series of new EHEDG Guideline Documents that focus on this correlation between design characteristics and obtainable cleaning results, among recently published guidelines like EHEDG Guideline Document 50 on the Hygienic Design Requirements for Cleaning-In-Place (CIP) Installations, and EHEDG Guideline 45 on Cleaning Validation, Monitoring and Verification. This newest EHEDG Guideline Document 51 on the Hygienic Design Aspects for Tank and Vessel Cleaning in the food industry completes this guideline cluster, and is now also ready for download from the EHEDG website: www.ehedg.org/guidelines

.

One guideline, various perspectives

EHEDG Guideline Document 51 is developed by experts who work in different areas of the food and food equipment industry, from hygienic design consultants and auditors to end-users of tanks who process different types of food products. The working group was also consulted by scientists who have performed extensive scientific research on the effectiveness of different types of tank cleaning. Last but not least, the working group also incorporated some of the largest tank cleaning machine vendors in Europe.

What differentiates tank cleaning from conventional CIP cleaning of pipe systems?

Bo Boye Busk Jensen, chair of the EHEDG Working Group Tank Cleaning, and R&D Engineer at Alfa Laval Tank Equipment: ‘This new EHEDG Guideline Document addresses one particular part of the CIP process: the tanks that are used throughout the industry for various types of food processing. Compared to CIP cleaning of pipe systems, the CIP cleaning of tanks is more challenging, because it’s much more difficult to obtain a consistent mechanical force on the inner surfaces of tanks and vessels than on the inner walls of pipes, where it often suffices to pressurise the cleaning fluids to obtain effective cleaning results.’

So you need different cleaning actions and different cleaning mechanisms inside the tanks?

Jensen: ‘Yes. You could do it with static spray devices, where you pour water into the tanks and then it runs down the tank surfaces. You can also use more advanced tank cleaning technologies, and all this is also included in the guideline that we are making. And then also the soiling itself is more severe in the tank, often because you have dry and semi dry conditions, while in a pipe system it will probably always be fully flooded with the product and you don't have these interfaces between product and air where you get more soiling where the soil layer can dry onto the surfaces and when it gets dried to the surfaces then it's more difficult to remove.

You focus both on the design of the tank itself, and on the design and the cleaning of the tank cleaning devices inside the tanks. Why did you decide to combine those two into one guideline?

‘The idea has always been to not only focus on on tank design and not only on tank cleaning but to put them together in one guideline, because there is a big interaction between the tank cleaning machine and the design of the tank itself, and you can't really take one and not talk about the other one. So that's the main reason why we have kept the tank design in the guidelines for now. There's been some discussion if we should have pulled it out and should have made a parallel standard or guideline for tanks, but we decided to keep it in for now, because then we have everything in one place, and it has been a benefit in our discussions to have it all in one place, because then we could go back and forth and change some recommendations to the tank cleaning device, depending on our recommendation for the tank design, for example.’

Many different types of tanks are used in many different areas of the food industry. How did you approach the complexity of this topic?

‘We included a table that provides an overview of the different types of soils and soiling characteristics that we encounter, and that offers a matrix pointing to the relevant sections in the guideline document. The reader then determines the best suitable tank cleaning technology to clean a particular tank with a particular purpose based on volume flow, or on time or on total cost of ownership. The guideline covers six different methods for tank cleaning, ranging from simple fill-and-dump-cleaning up to more sophisticated types of cleaning, like burst cleaning.

What are the advantages of more sophisticated types of cleaning related to more simple ones like fill-and-dump? Are you also addressing that in your guideline?

‘Yes we do. Comparing fill-and-dump to burst cleaning reveals the wide scope of this guideline, and how combining different types of cleaning technologies can offer major productivity and sustainability benefits. To save on the cleaning liquid for example, you can conduct a burst cleaning using any of the current tank cleaning device technologies that we have today: static devices or single-access devices or multi-access devices. You burst it using a limited amount of cleaning liquid, and then you let it rest there for two to five minutes to let the chemistry interact with the soil. The chemistry partly dissolves the soil and partly separates it from the surfaces. Then you add another burst, which will then run down the surfaces. You apply some chemistry, and combine that by removing the rest of the soil that has been loosened by the first burst of chemistry with a second burst cleaning action.’

Do you also address specific cleaning issues, related to agitators, for example?

‘Yes, this guideline also addresses the cleaning of agitators, because if you have an agitator, you often also have to deal with shadow zones, e.g. with surface areas in the tank that are difficult to reach for the agitator. We address different strategies to clean the agitators themselves, like letting it rotate slowly when you have a spray device that is spraying liquid onto it, or you can add spray devices beneath the agitator plate so that you can also clean the agitator from below.’

Besides focusing on food safety and food quality, various new EHEDG Guideline Documents also point to additional benefits of hygienic design, like the productivity and sustainability aspects. Does your guideline include those as well?

‘Yes, very much indeed. Optimising the effectiveness and efficiency of tank cleaning processes is the best and easiest way to significantly reduce water, energy and chemistry consumption. The potential savings are particularly high here because food processors can choose from a wide range of different tank cleaning technologies, that offer specialised ways for cleaning different types of tanks that are used for specific purposes. Many lightly soiled tanks can be cleaned quickly and effectively with just a static spray device for example, but the effectiveness of cleaning heavier soiled tanks can really benefit from more advanced tank cleaning devices that apply combinations of chemistry and mechanical force.’

What actual saving potentials can be realised by optimising tank cleaning?

'The potential savings are significant, and that’s supported by best industry practises throughout the industry that show evidence of water savings up to 70 to 75 percent and up to 50 percent of cleaning time reductions. This often results in productivity increases, since you save so much cleaning time, and in investment cuts as well, since you don't have to establish a parallel process line next to the one you already have in order to increase production.'

So, this guideline helps to improve on cleaning, as well as productivity and sustainability results?

‘Yes, it does.’