EHEDG Guideline 42, 'Disc Stack Centrifuges - Design and Cleanability' | New available guideline

Now available in our catalogue

EHEDG has released Guideline 42, ‘Disc Stack Centrifuges - Design and Cleanability’, an updated document on the hygienic design and cleaning of disc stack centrifuges used in the food and pharmaceutical industries. This resource defines specific terminology, outlines CIP procedures, and incorporates the latest scientific insights and legislative updates to ensure validated cleaning, product safety, and reliable machine operation.

To accompany the launch of the updated EHEDG Guideline on disc stack centrifuges, we spoke with Reinhard Moss, Senior Director Design Standards - BU Separators / Product Line Separators & Decanters (GEA Group), Chair of the EHEDG Working Group ‘Separators’.

Could you please introduce yourself and your background?

My name is Reinhard Moss, and I serve as Senior Director of Design Standards within the Business Unit Separators – Product Line Separators & Decanters at GEA. My journey began with a focus on milk separators, and over time, I took on increasing responsibility in this area. As the department grew, I became more involved in the development of hygienic design standards for our machinery. This work led me to travel to the United States to gain a deeper understanding of regulatory requirements, initially focusing on USDA standards, as there was no guidance for separators at that time. I began by working on USDA acceptance procedures, and as the industry evolved, I contributed to the development of the 3-A Sanitary Standards for separators. Beginning 2017 till 2022 I was member of the 3-A Board of Directors.

This marked the beginning of my long-standing engagement with hygienic design, which has since become a core aspect of my role. I was elected to serve as the Chair of the EHEDG Working Group ‘Separators’, which published Guideline 42, ‘Disc Stack Centrifuges - Design and Cleanability’ back in 2013.

Reinhard Moss

What prompted the revision of Guideline 42, and what key developments or industry needs does this new edition address compared to the original 2013 version?

The revision of Guideline 42 was primarily prompted by the five-year policy of EHEDG, which mandates regular reviews and updates of published documents to ensure they remain aligned with current industry standards and regulatory developments.

In this latest review, the main focus was on updating the references to norms, rules and regulations that have evolved since 2013. These adjustments were essential to ensure the guideline remains compliant with the latest requirements and maintains its relevance for both manufacturers and regulators. From a technical standpoint, the core design principles and hygienic engineering practices outlined in the original guideline remained largely unchanged. There were no significant innovations or changes in hygienic design for separators in the meantime. As such, the hygienic performance of the equipment described in the document has remained robust and effective over time. Most of the feedback incorporated during the revision process came from peers and industry experts who suggested improvements in clarity and wording, rather than proposing structural or conceptual changes. These refinements were aimed at enhancing the document's usability and interpretability, ensuring that the content is more accessible and easier to implement across the industry.

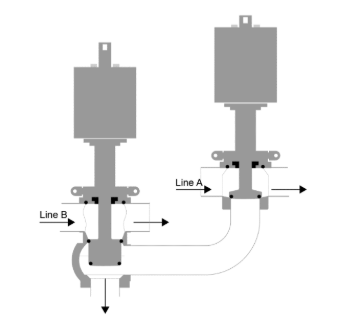

How does the document address the specific cleanability challenges posed by high-speed centrifugal force and complex internal geometries?

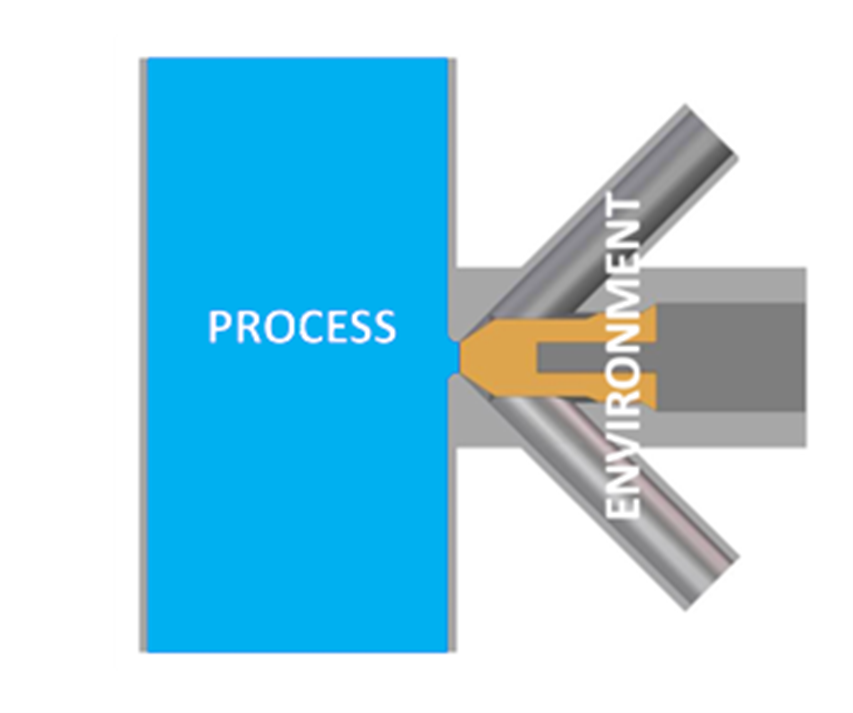

Indeed, one of the core challenges in designing separators for hygienic applications lies in their complex internal geometries and the high-speed centrifugal forces they operate under. These machines often involve very compact structures with narrow internal spaces, which make cleanability a particular concern.

Early on, it was technically challenging to incorporate all the necessary radii, gasket grooves and other hygienic design features into such tight constructions. However, over time, the industry, including our own team at GEA, has developed reliable fabrication methods that enable even very small and complex machines to meet hygienic design standards effectively. The guideline addresses these challenges by outlining specific design recommendations that take into account the intricacies of centrifugal systems. This includes best practices for ensuring that all product-contact surfaces are fully drainable, accessible for cleaning and free of crevices or dead spaces, where residues could accumulate. Additionally, particular attention is given to the integration and positioning of gaskets, grooves and sealing elements, ensuring that these do not hinder cleaning processes and can withstand repeated cleaning cycles without degradation.

At GEA, we continuously train our design engineers, especially new team members, in the principles of hygienic design. Through dedicated workshops and knowledge-sharing sessions, we ensure that all staff is well-versed in how to apply these principles to our machinery. This structured internal education has helped us maintain a consistent and high standard of hygienic design across our product lines. While these challenges remain ongoing due to the evolving nature of machinery and product requirements, the guideline provides a solid framework that helps manufacturers like us navigate these complexities and deliver equipment that meets both performance and hygiene expectations.

What are the most critical design features that manufacturers should pay attention to when aiming to meet the hygienic requirements outlined in this document?

There are several critical aspects in separators, but as I already mentioned, one of the main challenges lies in the small areas that you simply can’t avoid. These machines are complex by nature, and there are many very tight, narrow areas inside them. Those specific spots require special attention—they need to be closely examined and treated carefully, because that’s where hygienic design can be most difficult to apply. It's essential to focus on these challenging areas to ensure that the overall hygienic requirements are truly met.

We would like to thank the current contributors—Thomas Kleimann (GEA Westfalia Separator Group GmbH), Luca Marcante (SPX Flow Santorso s.r.l.), Anette Rangmark (Alfa Laval Technologies AB), and Gunter Zimmermann (Nestlé Nutrition)—and acknowledge the authors of the first edition of this document (April 2013) for their invaluable contributions: Karl-Heinz Ahrens (Kraft Foods Deutschland Services GmbH & Co. KG), Matthias Balley (VDMA), Hans-Werner Bellin (BELLIN Consult), Anneginus Hummel (Friesland Campina Nederland B.V), Erik-Ole Jensen (Arla Foods), Jacques Kastelein (TNO), Etienne Morvillier (Nestlé Product Technology Centre), Dr. Frank Nitzsche (IngFN – Ingenieurbüro), Susanna Norrby (Alfa Laval Tumba AB), Anette Rangmark (Alfa Laval Tumba AB), Ettore Spinato (SPX Flow, former SEITAL Separatori Italia S.r.l), Christian Trägardh (Food Engineering Chemical Centre, University of Lund), Carsten Waubke (GEA Westfalia Separator GmbH), and Reinhard Moss (GEA Westfalia Separator Group GmbH).