EHEDG Guideline 28, ‘Safe and Hygienic Treatment, Storage and Distribution of Water in Food and Beverage Factories’ | New available guideline

Now available in our catalogue

EHEDG has released a revised version of Guideline 28, ‘Safe and Hygienic Treatment, Storage and Distribution of Water in Food and Beverage Factories’. This updated edition reflects recent technological advances, increasing sustainability goals, and the growing need for clear hygienic design principles in water systems throughout food production environments.

Why a revision was necessary

Water is essential to food safety and hygiene, but it's not a sterile medium. Even drinking water — safe for human consumption — can pose microbiological risks in food and beverage manufacturing if not handled correctly. As Dr Anett Winkler, microbiologist at Cargill and Chair of the EHEDG Working Group ‘Water Management’, explains: “While drinking water is safe to drink, it is not sterile. Therefore, its quality needs to be controlled to avoid safety risks, both for the product and for employees.”

The revised guideline responds to a growing need for improved water stewardship, especially in light of sustainability pressures. In recent years, water reuse has become a critical area of interest for food producers. The updated document now includes:

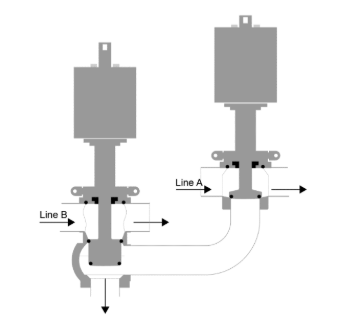

Guidance on water reuse from sources like condensate, stormwater, and process water

Expanded risk assessment procedures

Considerations for non-traditional water sources

Identification of relevant contaminants for each application

Practical advice on monitoring and treatment systems

Addressing the complexities of legacy systems

One of the most challenging aspects of water management in food factories is the often fragmented state of distribution systems. Many networks are decades old and contain a mix of components, some undocumented or improperly modified over time. “Distribution maps are often outdated or incomplete, which makes monitoring and maintenance difficult,” says Anett. Dead ends, poorly located sampling points, and incompatible materials pose persistent hygienic risks — risks that the new guideline addresses with actionable design and inspection guidance.

Enabling sustainable water reuse — safely

The revised guideline helps manufacturers move forward with safe water reuse practices by aligning water quality requirements with application-specific needs. It outlines a step-by-step approach that starts with thorough risk assessment, continues with appropriate treatment selection, and ends with tailored monitoring strategies. With no universal solution available, the document presents a flexible framework adaptable to different plant configurations and risk profiles. This empowers producers to reduce water waste without compromising hygiene or product safety.

Download the Guideline

EHEDG Guideline 28 (3rd Edition) is now available for download. It’s an essential resource for food and beverage manufacturers looking to modernise water systems, improve sustainability, and reduce risk in water handling operations.

Thanks to all contributors: Andreas Wirth & Joerg Berger (Krones), Carsten Vigen Hansen (Tetra Pak), Daniel Araujo Ribeiro (Diversey), Dirk Nikoleiski (Commercial Food Sanitation), Esmeralda Paz Lemus (LEFIX y Asociados), Francisco Pedrosa (Spiraxsarco), Harshad Joshi (Reckitt), Javier Lemus (ACO), Lars van Egmond (Ecolab), Laurie A. Gilmore (Coca-Cola), Luigi Martinesi (delta Projects Sàrl) & Olivier Rondouin (Doceor).