EHEDG Guideline 29 - Part 2, ‘Hygienic Design of Packaging Systems for Solid Foodstuffs – Thermoforming Machinery’ | New available guideline

Now available in our catalogue

EHEDG has released Guideline 29 - Part 2, ‘Hygienic Design of Packaging Systems for Solid Foodstuffs – Thermoforming Machinery’. Building on the general framework of Part 1, this edition offers specific guidance on thermoformers, widely used in food processing, with a focus on open zones, contamination risks, and practical collaboration between machine builders and food producers.

Why a dedicated guideline for thermoforming machines?

EHEDG Guideline 29 Part 1 introduced a broad framework for applying hygienic design and risk assessment principles to packaging machinery. But it did not dive into the distinct requirements of specific technologies — a gap now addressed by Part 2.

“Part 2 extends the foundational concepts to the case of thermoforming packaging machines, which are commonly used across the food industry,” explains Peter Golz, Chair of the EHEDG Working Group ‘Packaging Machines’.

Co-Chair Tobias Braunegger, hygienic design specialist at Multivac, adds: “Thermoforming machines are widely applied, especially for solid and microbiologically sensitive food products. So they were a logical first focus for a dedicated follow-up.”

Addressing hygienic risks in the open zone

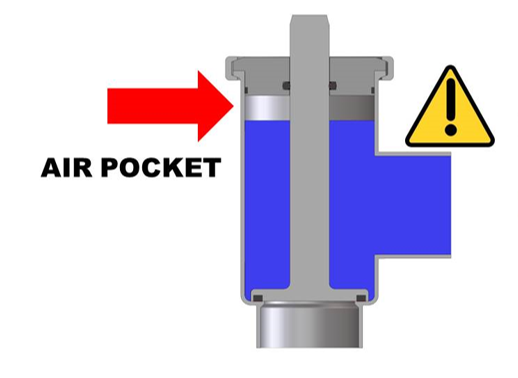

A major focus of the new guideline is on the open product loading zone — a critical control point where contamination could persist throughout packaging.

“The most critical hygienic area is the open zone where product is filled into the formed packaging cavities,” says Tobias. “Contamination here would be especially problematic because this is the final point before sealing — meaning any recontamination at this stage stays inside the package.”

Sources of contamination may include overhead components such as lighting or cabling, manual or automatic loading operations, or even the packaging material itself. Human interaction, in particular, poses a persistent risk.

“Thermoforming lines are often manually loaded, and operators represent a hygiene risk,” notes Peter. “The guideline includes a comprehensive table of ‘weak spots’ — specific risk-prone areas — and links them to required risk assessment and mitigation steps.”

Enabling collaboration through shared hygiene classifications

Another key advancement in Part 2 is its facilitation of clear communication between food producers and equipment suppliers. Using a hygiene classification system first introduced in Part 1, this follow-up adds practical examples to help align expectations and requirements.

“We provide examples of product types typically packed on thermoforming machines — allowing food producers to match their hygiene needs to the appropriate class and clearly communicate those expectations to machine suppliers,” explains Tobias.

Download Now

EHEDG Guideline 29 - Part 2 is now available for download at www.ehedg.org. It is an essential resource for any stakeholders involved in designing, specifying, or integrating thermoforming machinery in food processing environments.

We would like to thank Peter, Tobias and the other Working Group members: Anil Patel (Pepsico), Aritz Murgia & Juanjo Jauregi (ULMA Packaging), Detlef Volmer (GEA), Fredrik Hansen (Tetra Pak), Janyce Franc (STERIXENE), Marco Nese (Habasit), Markus Robert Lamche (Voestalpine), Martin Leetz (Weber Maschinenbau GmbH Breidenbach), Max Hesse (Fraunhofer IVV) & Pete Gibson (Marel LTD).

Watch the full interview with Peter and Tobias here below.