EHEDG Authorised Testing Laboratories meeting in Germany

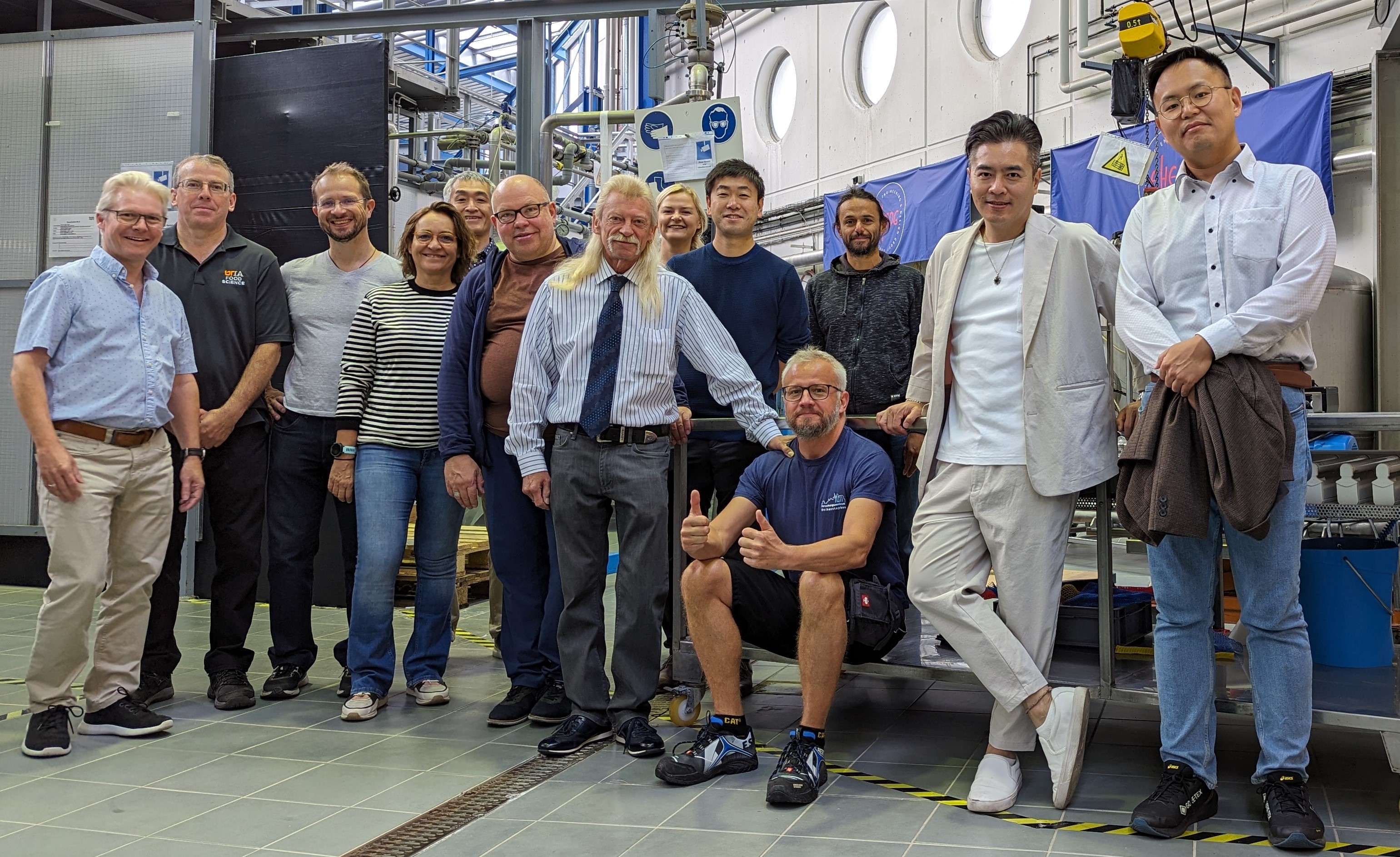

Every piece of equipment (open and closed) considered for certification must be evaluated by one of the EHEDG Authorised Evaluation Officers (AEOs), at one of the EHEDG Authorised Testing Laboratories (ATLs). The labs are in active exchange with each other, but usually only online. Once a year, a visit to one of the facilities takes place to discuss the tests performance in depth, as well as to interpret their results. This year it was Germany's turn, with the Fraunhofer IVV research institute in Dresden and the Weihenstephan Research Centre BLQ in Freising/Munich.

in the photo, left to right: Jürgen Hofmann (Hygienic Design Weihenstephan), Mark Morgan (University of Tennessee), Nicolas Rossi (Idele), Irene Llorca (AINIA), Tadashi Tsuchiya (Japan Food Research Laboratories), Alan Friis and Natacha Holmud (FORCE Technology), Andy Timperley (Andy Timperley Consulting), Kiichiro Saito (Japan Food Research Laboratories), Giampaolo Betta (SIIIA), Achim Zeidler (Hygienic Design Weihenstephan), Yu Ming Chen and Shih Rong Huang (FIRDI).

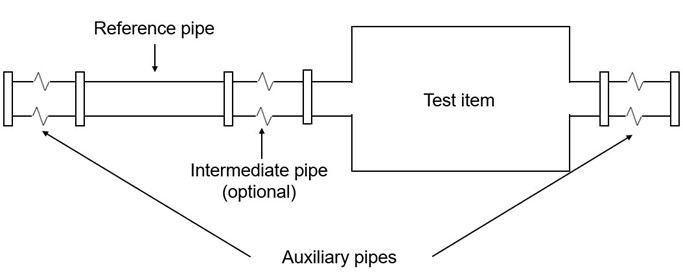

The meeting started at the Fraunhofer IVV Research institute in Dresden with the Open Process Cleaning (OPC) test. Food processors are increasily concerned about how their processing equipment and the inerconnectivity of individual parts may adversely impact the wholesomeness of the processed foods. It is then crucial to ensure that the exterior surfaces of equipment in OPC applications do not contribute to potential contamination risks within the processing environments. This OPC testing (and future certification) provided by EHEDG will assist the equipment manufacturers and the food processing companies to meet the risk assessments criteria.

After two days of fruitful discussions on the integration of this new test into the EHEDG certification scheme, the EHEDG Authorised Evaluation Officers moved on to Weihenstephan. Here more discussions on the cleaning tests were carried out, with a double screw pump and a sensor in a T-piece as samples.

These meetings are fundamental to exchange input and to enhance the test method. With this in mind, the EHEDG Authorised Evaluation Officers are already looking forward to next year's visit to the FORCE Technology laboratory in Denmark.