EHEDG Guideline 20, ‘Hygienic Design and Safe Use of Mixproof Valves’ | New available guideline

Now available in our catalogue

EHEDG has released the updated edition of Guideline 20, ‘Hygienic Design and Safe Use of Mixproof Valves’, offering a modernised resource for engineers, equipment manufacturers, and food producers. This revised document brings new clarity to hygienic and functional valve design in today's highly automated and safety-critical food processing environments.

Updated graphics and refined scope

Originally published in 2000, the guideline has undergone a major overhaul — not only in terms of content but also visual presentation.

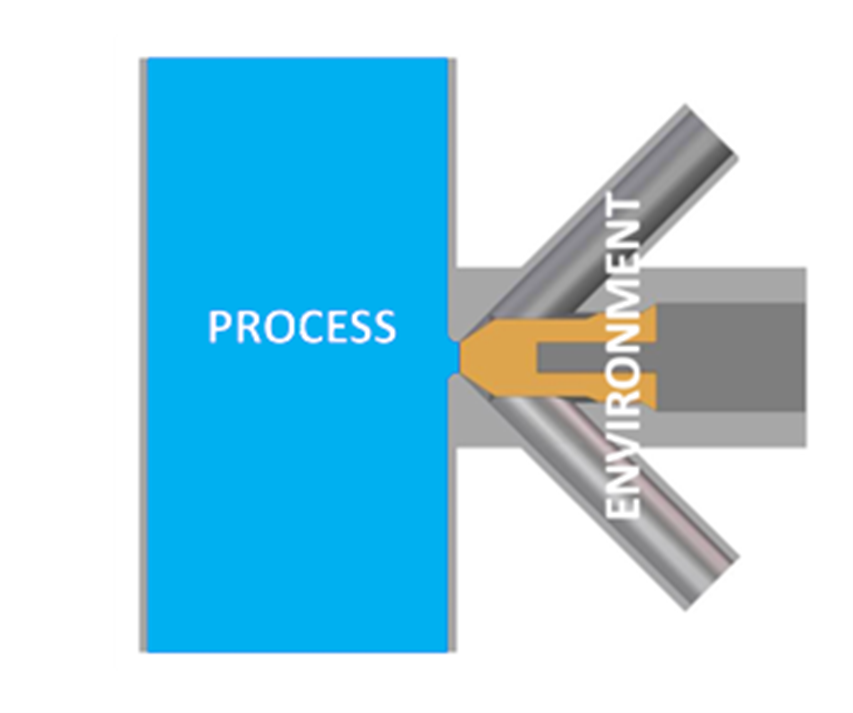

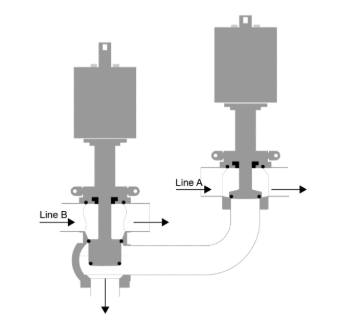

“One of the most noticeable improvements lies in the graphical representations,” says Uwe Heisswolf, Chair of the EHEDG Working Group ‘Valves’ and Head of Product Development at Kieselmann GmbH. “These have been redesigned to appear more neutral and technical, making it easier to visually support and clarify the content.”

In addition, the updated guideline separates out the topic of aseptic valve design into a dedicated supplement, allowing this edition to focus exclusively on the hygienic design of mixproof valves.

Design variants, balancing, and cleanability

The guideline outlines several seat and shaft design options without ranking them, allowing users to select what best fits their systems and philosophies. A key area of functional concern is pressure balancing, especially in double-seat valves that manage simultaneous flows or segregate product streams.

“From the perspective of our Working Group, a balanced piston design is absolutely essential for double-seat mixproof valves,” notes Uwe. “Balanced pistons reduce the mechanical load, enhance safety, and ensure more stable operation — especially during pressure shocks.”

Balancing complexity with hygienic integrity

In today’s automated processing environments, valves are more than on/off switches — they control, regulate, protect, and manage complex flow networks. With that comes the challenge of integrating hygienic principles into sophisticated mechanical systems.

“Ultimately, all hygienic design principles focus on one goal: ensuring the cleanability of product-contact surfaces,” says Uwe. “The simpler the design, the easier it is to clean — but we must also meet growing functional demands.”

Get the Guideline

EHEDG Guideline 20 is available now for download. Whether you’re designing new systems or upgrading existing ones, this document helps align safety, performance, and compliance in valve technology.

Thanks to all other contributors: Andreas Ritzl (Gebr. Rieger GmbH + Co. KG), Bertil Andersson, Carsten Rosendal & Karen R. Rasmussen (Keofitt), Catarina Melo (Danone), Christian Geubert (Angst+Pfister), Constantinus Anastasyadis (Evoguard), David Blackwell (Nestle), Elena Zuck (GEMÜ), Fedja Voss (GEA), Jonas Stinnerbom (Tetrapak), Karl-Åge Lindholm (Alfa Laval), Luca Ollari (Bardiani Valvole s.p.a.), Maxime Paraud (Definox), Norbert Spliethoff (SPX Flow) & Roland Cocker (Cocker Consulting).